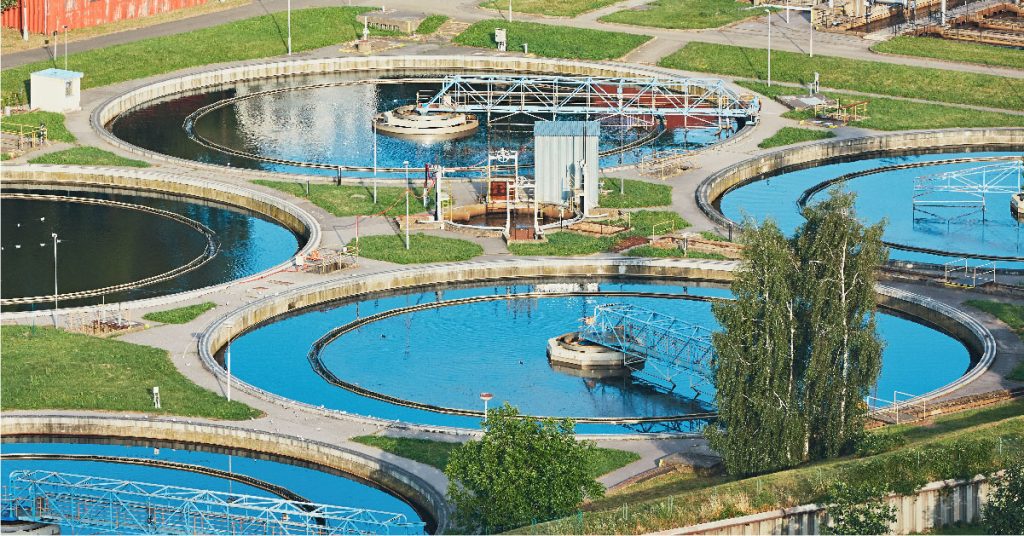

Industrial wastewater treatment plays a pivotal role in sustainable industrial development and environmental protection, particularly in regions like the UAE, where water scarcity and strict environmental regulations make effective water management essential. By understanding the treatment of industrial wastewater, industries can ensure compliance, optimize resource usage, and reduce environmental impact. This blog explores key methods for industrial wastewater treatment, the role of industrial water treatment chemicals, and the importance of advanced industrial water treatment systems in the UAE.

Why Industrial Waste Water Treatment Is Important?

Industries generate wastewater containing pollutants such as heavy metals, oils, chemicals, and organic matter that can harm ecosystems and public health if untreated. The treatment of industrial wastewater is essential for:

- Compliance: Meeting UAE’s environmental regulations and standards.

- Resource Optimization: Recycling and reusing treated water in industrial processes.

- Environmental Protection: Reducing pollution and conserving water resources.

Effective industrial wastewater treatment combines advanced processes and tailored industrial water treatment systems to address diverse pollutants.

Key Methods for Industrial Waste Water Treatment

Different industries produce varying types of wastewater, requiring specific treatment methods. Here are the most effective techniques for the treatment of industrial wastewater:

1. Primary Treatment

The first step in the industrial water treatment process focuses on removing large solids, oils, and greases from the wastewater. Key processes include:

- Screening: Physically removes large debris and solid particles.

- Sedimentation: Allows suspended particles to settle at the bottom of the treatment tanks.

- Oil and Grease Separation: Skimmers or flotation devices remove floating oils and grease.

This stage prepares the wastewater for more advanced treatment processes.

2. Secondary Treatment

This stage focuses on removing dissolved and suspended organic matter through biological processes. Common methods include:

- Activated Sludge Process: Microorganisms break down organic matter in aerated tanks.

- Trickling Filters: Wastewater is sprayed over a bed of rocks or plastic, where microorganisms consume the contaminants.

- Anaerobic Digesters: Organic pollutants are broken down in the absence of oxygen, generating biogas as a byproduct.

Secondary treatment effectively reduces the biological oxygen demand (BOD) and chemical oxygen demand (COD) in wastewater.

3. Tertiary Treatment

Tertiary treatment ensures the removal of finer contaminants, making the treated water suitable for reuse or safe disposal. Processes include:

- Filtration: Sand filters or membrane systems remove remaining suspended solids.

- Chemical Treatment: Industrial water treatment chemicals, such as coagulants,

Flocculants, and disinfectants, eliminate specific impurities and pathogens. - Advanced Oxidation: Techniques like UV radiation or ozonation degrade hard-to-remove organic compounds.

Tertiary treatment is crucial for achieving the high purity levels required in the UAE’s water-scarce environment.

4. Zero Liquid Discharge (ZLD) Systems

ZLD systems ensure no wastewater leaves the industrial premises, promoting maximum water reuse. These advanced industrial water treatment systems use processes like:

- Evaporation: Concentrates the wastewater to extract reusable water.

- Crystallization: Converts remaining liquid waste into solid waste for disposal.

ZLD systems are gaining traction in the UAE due to their ability to conserve water resources and meet stringent environmental standards.

The Role of Industrial Water Treatment Chemicals

Industrial water treatment chemicals play a vital role in ensuring the efficiency and effectiveness of wastewater treatment processes. These chemicals address specific treatment needs, such as:

- Coagulants and Flocculants: Facilitate the aggregation and removal of fine particles and suspended solids.

- Corrosion Inhibitors: Protect industrial water treatment systems from corrosion.

- Scale Inhibitors: Prevent the buildup of scale on equipment and pipelines.

- Disinfectants: Eliminate harmful microorganisms and pathogens.

- pH Adjusters: Maintain optimal pH levels for various treatment processes.

Selecting the right industrial water treatment chemicals is critical for achieving desired outcomes and maintaining system efficiency.

Industrial Water Treatment Systems in UAE

The UAE’s arid climate and limited freshwater resources necessitate advanced industrial water treatment systems that can recycle and reuse water efficiently. Modern systems include:

1. Membrane Systems

- Reverse Osmosis (RO): Removes dissolved salts and impurities, producing high-purity water.

- Ultrafiltration (UF): Filters out suspended particles, bacteria, and some viruses.

2. Effluent Treatment Plants (ETPs)

ETPs combine primary, secondary, and tertiary treatments to handle diverse industrial wastewater streams.

3. Efficient Cooling Water Systems

Specialized systems treat and recycle water used in industrial cooling towers, reducing water wastage.

4. Biological Treatment Systems

These systems harness microbial activity to treat wastewater in an environmentally friendly manner.

Benefits of Effective Industrial Waste Water Treatment

Implementing effective industrial water treatment processes offers several advantages:

- Cost Savings: Reducing water consumption and recycling treated water lowers operational costs.

- Regulatory Compliance: Ensures adherence to UAE’s strict environmental regulations.

- Improved Equipment Longevity: Proper treatment prevents scaling and corrosion, enhancing the lifespan of industrial equipment.

- Environmental Conservation: Reduces pollution and conserves limited water resources.

Cutting-Edge Waste Water Treatment Solutions by Ion Exchange

Ion Exchange pioneers water management solutions by focusing on wastewater recycling and source reduction, while their waste management systems emphasize product recovery and waste minimization. They utilize integrated systems that incorporate innovative, energy-efficient, and cost-effective technologies like membranes, advanced oxidation, and evaporation. These systems conserve water by recycling wastewater and recovering valuable products for reuse, achieving zero liquid discharge objectives. This not only provides customers with a strong return on investment but also contributes to environmental protection.

Ion Exchange carefully selects the most appropriate technologies based on thorough studies, surveys, and pilot testing. Their solutions cater to various industries, including power plants, fertilizers, electronics, textiles, chemicals, food & beverage, pulp & paper, pharmaceuticals, and automotive sectors, enabling efficient recovery and reuse of water and products. Our products include:

Conclusion

Industrial wastewater treatment is essential for sustainable industrial growth and environmental preservation in the UAE. By leveraging advanced technologies, industrial water treatment chemicals, and efficient systems, industries can optimize water use, reduce environmental impact, and comply with regulations.